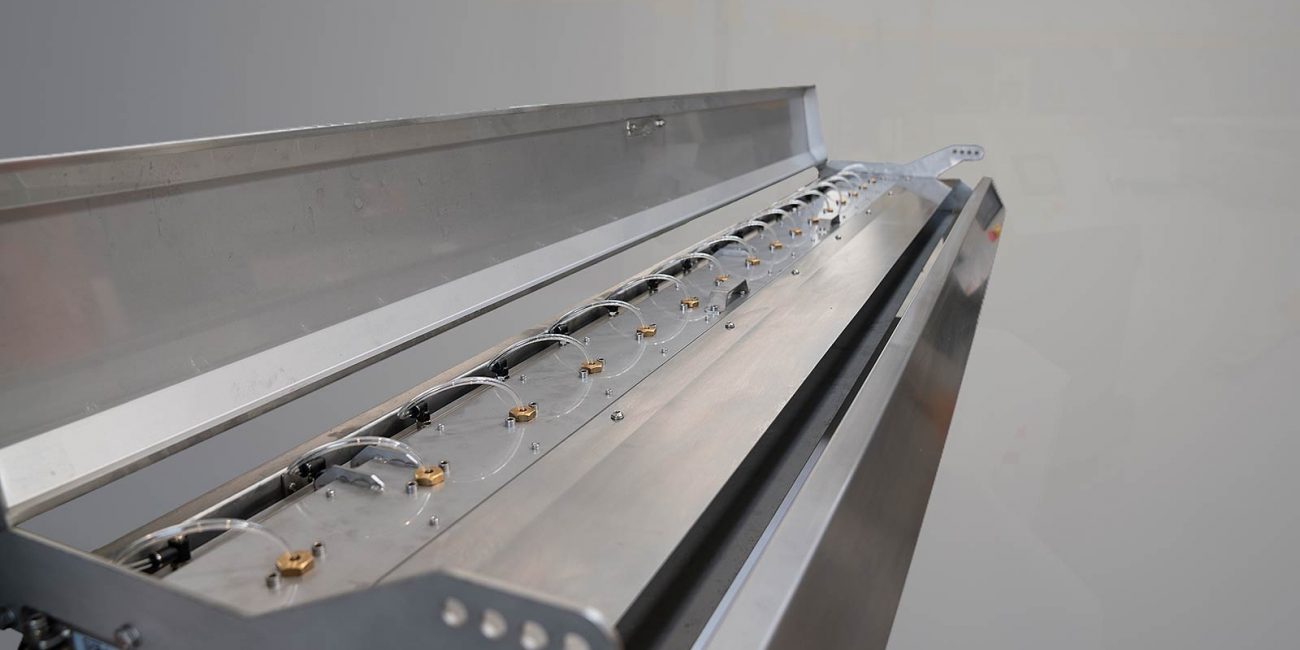

It can be easily applied to machines such as any brand of stenter, sanforizer, packaging, quality control and finishing machine. Our product, which regains its natural moisture lost during finishing, helps to maintain the surface quality of the fabric by creating a decent touch. The unit, which operates with the rotating plates manufactured with stainless high quality bearings and which operates with the principle of water spraying, has a long life with its material quality. It is designed for simple usage and structured according to the wishes of the user, and its easy of use and adjustment is provided. In case of errors and malfunctions that may occur with the help of the sensors used, the alarm menu warns the user with the warnings such as “no water”, “belt broken” and “inverter failure”.

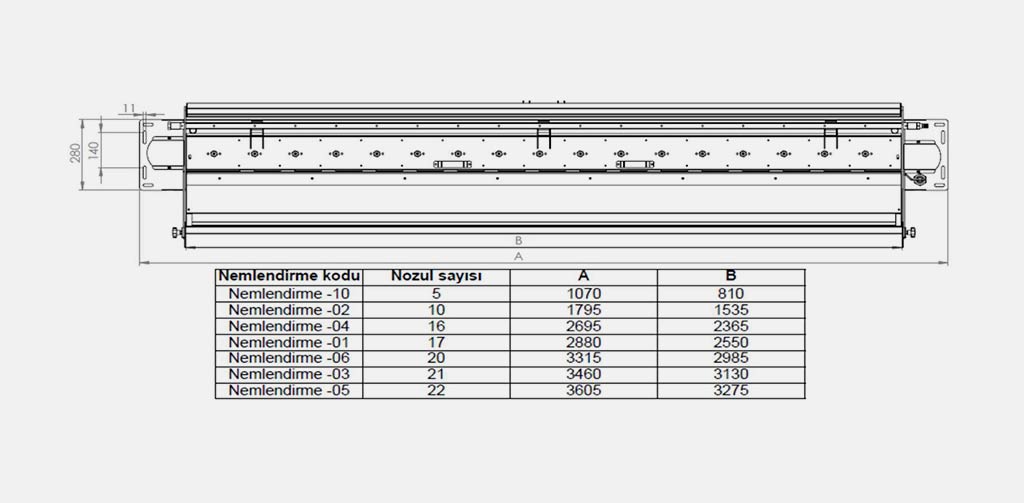

Spray Unit

GENERAL FEATURES

• COMPATIBLE WITH EVERY BRAND RAM, STENTER, PACKAGING, QUALITY CONTROL AND FINISHING MACHINES

• CREATING A QUALITY DECENT TOUCH ON THE FABRIC SURFACE BY REGAINING REQUIRED HUMIDITY

• DESIGNED PERFECTLY, NOT CLOGGING, ROTARY PLATE NOZZLE

• FABRIC HOMOGEN PULVERIZATION

• PULVERIZED WATER SPRAYS TO PREVENT WATER DROP STAIN IN THE FABRIC

• REQUESTED HUMIDITY AMOUNT SETTING

• WATER LEVEL MEASUREMENT AND WARNING

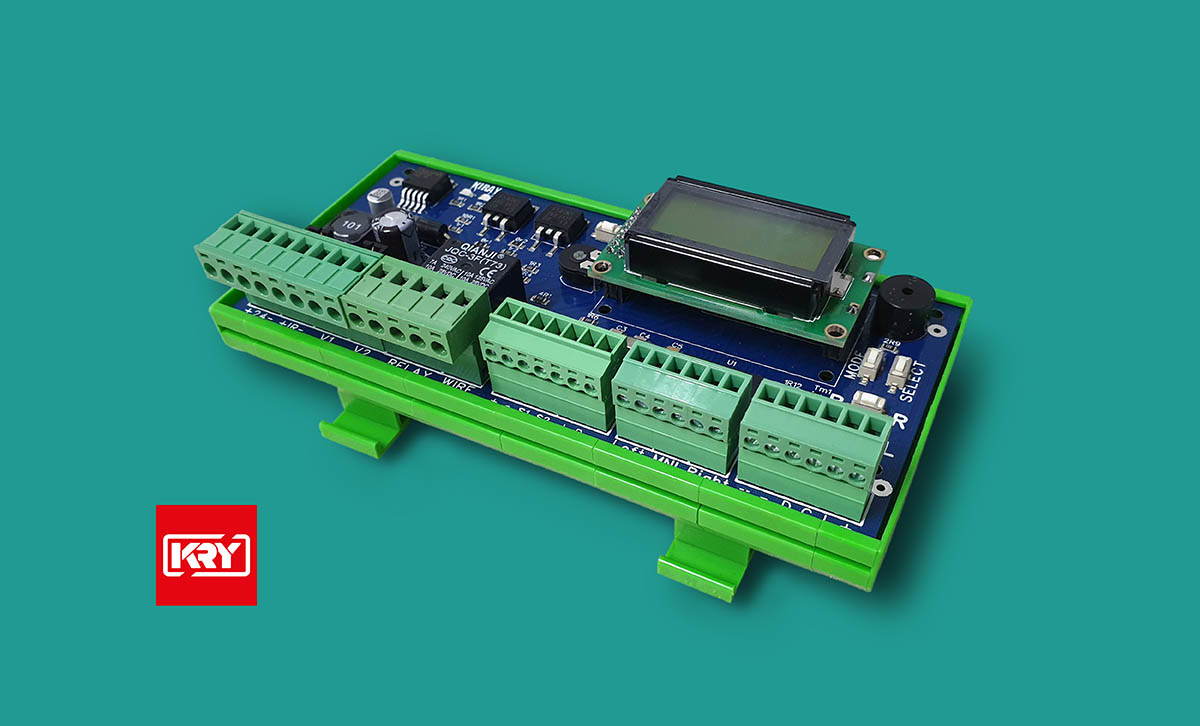

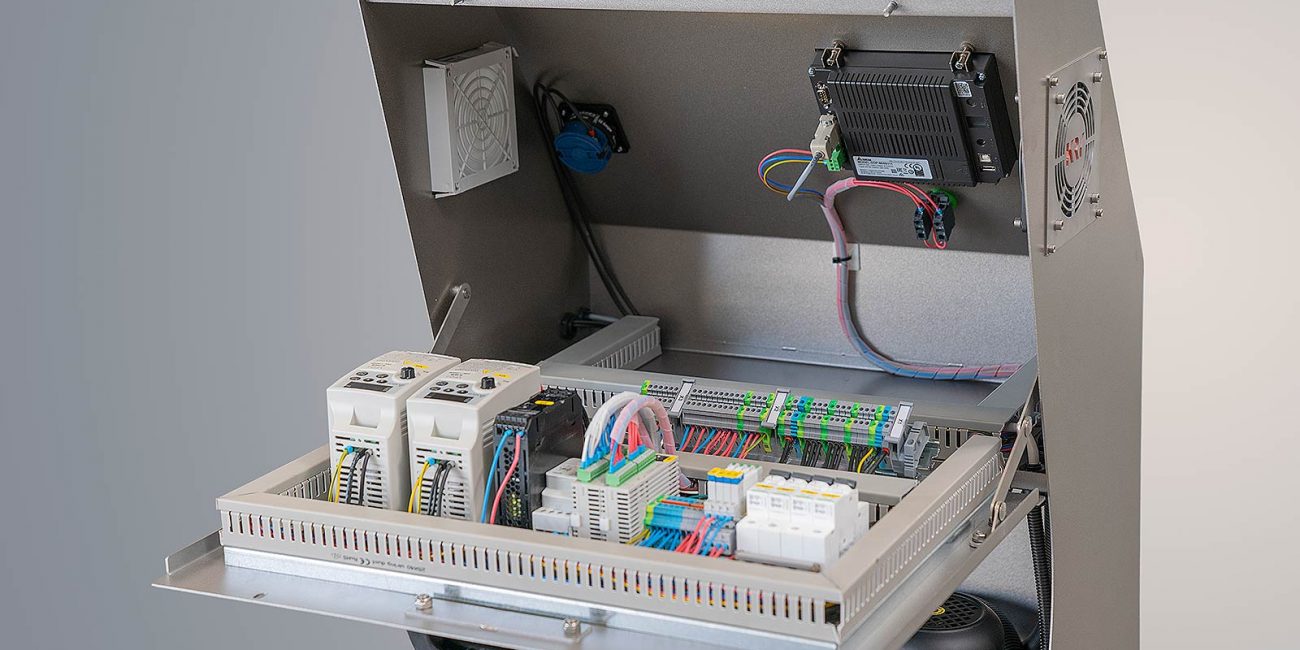

• OPERATOR-FRIENDLY USER PANEL AND INTERFACE REPORTING FAULT AND WARNINGS

• EASY AND PRACTICAL CARE WITH CUSTOMER ORIENTED DESIGN

TECHNICIAL SPECIFICATIONS

| ELECTRIC INPUT VOLTAGE | 230 V AC /380 V AC – 50Hz/60 Hz |

| CONTROL VOLTAGE | 24V DC |

| INSTALLED POWER | 7,5 KW |

| HUMIDIFICATION RATE | %1 – %10 |

| WORKING AIR PRESSURE | 4 – 8 BAR |

| NUMBER OF NOZZLE | 5 – 23 |

| OPERATING TEMPERATURE | 5 – 60° C |

| BODY MATERIAL | AISI 304 STAINLESS STEEL |

| MACHINE WEIGHT | 120 KG |