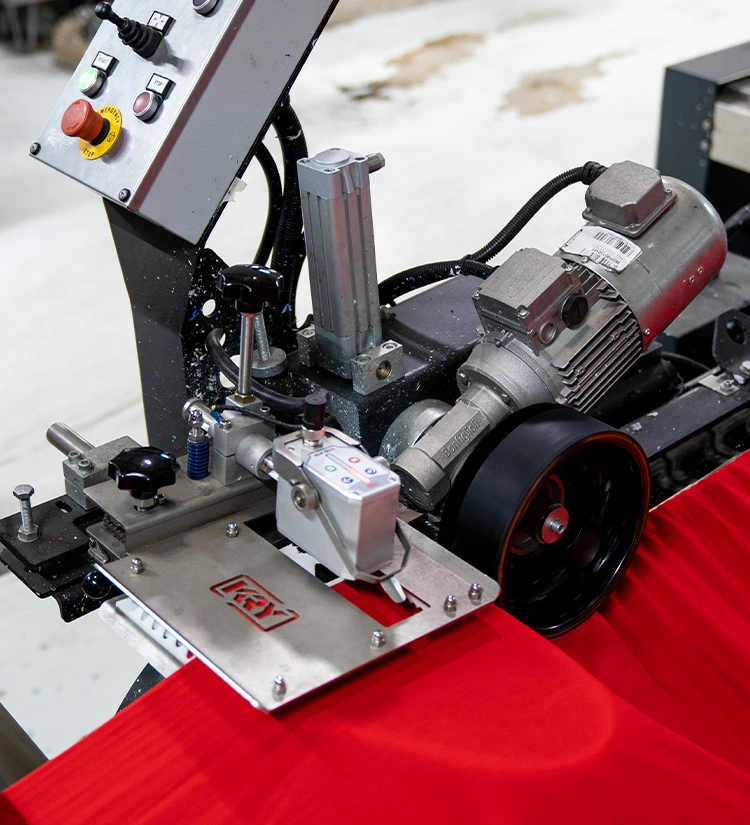

Mechanical and electrical connection is possible for all brands of stenter and sanforising machines. It provides a perfect spreading before cutting with its vertical and horizontal angles and pressurised air. With its carbonised steel blade hardened with special techniques and cutting angle determined by engineering calculations, a perfect cut is achieved. Fine cutting up to 1 centimetre is possible. The cutting angle determined by calculations and experience and the timer-adjustable pump lubrication system offer the user a blade life of 30 to 60 days without sharpening. The cutting drive power of the blades is provided by a 0.37kw asynchronous ELK motor. Sicak brand point tracking sensor can make precise adjustment in fabric edge tracking.

| MINIMUM CUTTING WIDTH | 5 mm |

| ELECTRIC SUPPLY VOLTAGE | 230 V AC / 3 x 400 V AC 50 or 60 Hz |

| CONTROL VOLTAGE | 24V DC |

| MOTOR POWER | 0,37 KW |

| BLOWER MOTOR POWER | 3 KW |

| MAX WORKING SPEED | 65 m/min |

| OPERATING TEMPERATURE | 5 – 60° C |

| BODY MATERIAL | AISI 304 STAINLESS STEEL |

| UNIT WEIGHT | 80 Kg (INCLUDING PANEL, RIGHT AND LEFT UNIT |