EFFICIENCY

Energy Efficiency

%30-50 ELECTRICITY SAVINGS

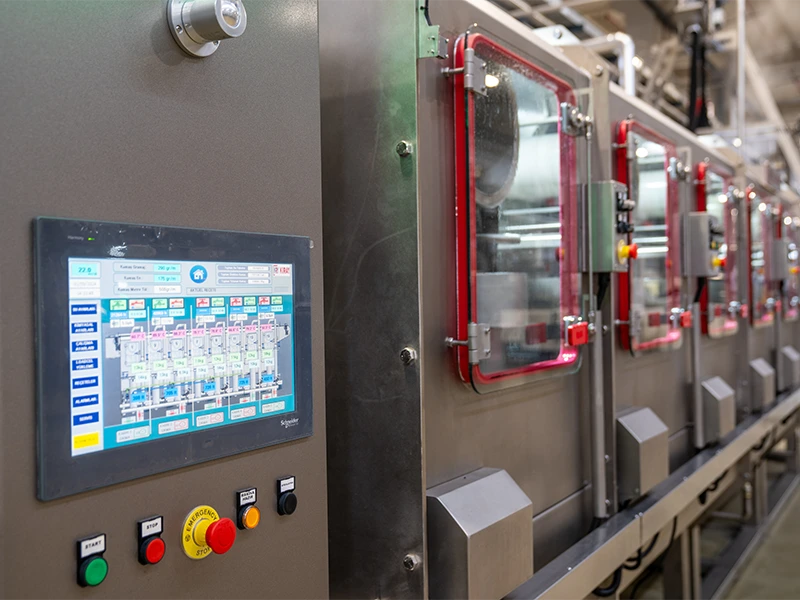

Ensures fast and economical washing of printed fabrics after the fixation process. The KIRAY HYM-1923 P Rope Washing Machine can also perform reactive post-printing washing with systems such as cold/hot soaking and cold/hot drum washing added to the machine’s entrance. It is an operator-friendly washing machine, designed for ease of use.

%30-50 ELECTRICITY SAVINGS

HIGHER FASTNESS

%40-50 CAPACITY INCREASE

%50-80 WATER SAVINGS

%50-80 STEAM SAVING

The KIRAY HYM-1923 P Rope Washing Machine works harmoniously and efficiently with the KIRAY Rope Opening Machine located at the exit of the rope washing machine. It is an operator-friendly washing machine, designed for ease of use. The heating system is equipped with a heat exchanger, allowing a maximum heating temperature of 98°C. Additionally, the adjustable overflow level feature with the pumped overflow function ensures maximum washing efficiency with minimal water consumption. It provides flexibility for different fabric types.

The KIRAY HYM-1923 P Rope Washing Machine consists of 6 baths, 20 J-boxes, and 40 washing nozzles.

Effective and gentle washing with a 140 mm nozzle diameter.

It consists of combinations containing 2 and 4 j-boxes.

5-50 kg fabric capacity

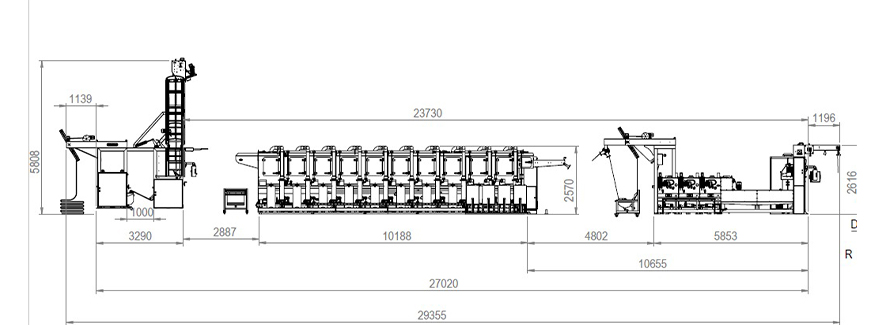

| Complete Line Dimensions | 4727 x 29335 x 5800 mm |

| Fabric Type | 100% Cotton Knit/Viscose/Polyester/Woven |

| Fabric Weight Range | 80-400g/m2 |

| Production Speed | 5m/min. (minimum)., 60m/min. (maximum) |

| Supply Voltage | 380VAC 50/60Hz |

| Control Voltage | 24VDC |

| Installed Power | 62kW *VARIES ACCORDING TO EQUIPMENT* |

| Open-Width Washing | 20kW |

| Rope Washing Part | 40kW |

| Rope Opener Machine | 22kW |

| Steam | 5.5-6 Bar Pressure (Consumption: 0.7-0.9 steam kg/fabric kg) |

| Compressed Air | 6-8 Bar Pressure |

| Washing Water | 2-3 Bar Pressure |

| Water Consumption | 6-25 Lt for 1 kg fabric washing after printing |

*Variables such as quantity, fabric type, fabric fiber composition, types of dyeing/printing chemicals, their concentrations on the fabric, etc., may affect water consumption. Generally, the deviations from the provided values are minimal.